Products

Our ideas

Leader on the market for quality, design and image

We aim to enhance the quality concept, set new standards and employ all the technological design available to express Spencer's new point of view on high quality devices. The result of this work, carried out with intuition

and inventiveness, are projects that have created a global range of proposals that reduce fatigue on the part of the operators and at the same offer improved services. In a short time, in fact, Spencer's devices have become a synonym of high quality and prestige in this sector: the most qualified focus able to match traditional excellence and technology in the field of recovery, moving and transport of corpses. The range of models found on the market is evidence

of an indisputable success.

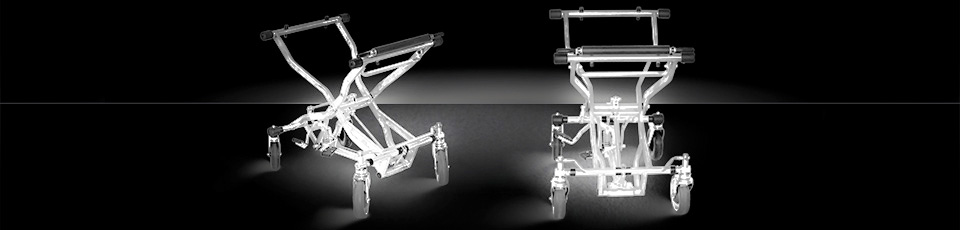

Leverage telescopic support to improve the steering.

Leverage telescopic support to improve the steering.

Adjustable heights trolley for the transport of coffins to improve the transferring manoeuvres.

Adjustable heights trolley for the transport of coffins to improve the transferring manoeuvres.

The variable heights allow easy transfer and avoid effort during corpse dressing.

The variable heights allow easy transfer and avoid effort during corpse dressing.

We can manufacture new versions with adapted dimensions and personalise the surface treatments and colours.

We can manufacture new versions with adapted dimensions and personalise the surface treatments and colours.

Back support

Often the staff in charge of funeral services perform the transportation and movement of the corpse or coffin, without the necessary equipment. In fact rachis overload and lower back pain are very frequent problems for them. Apart from not complying with the current regulations, we also encounter problems with organisation and with the quality of the services provided.

To prevent these problems and at the same time protect operators and increase their comfort and security, Spencer proposes a range of back-saving products that allow the customers to individuate the most suitable solution for their needs and the best solution for each type of work they need to do.

Often the staff in charge of funeral services perform the transportation and movement of the corpse or coffin, without the necessary equipment. In fact rachis overload and lower back pain are very frequent problems for them. Apart from not complying with the current regulations, we also encounter problems with organisation and with the quality of the services provided.

To prevent these problems and at the same time protect operators and increase their comfort and security, Spencer proposes a range of back-saving products that allow the customers to individuate the most suitable solution for their needs and the best solution for each type of work they need to do.

| Salvaschiena |

Twist effect

Twist was created to fill a gap in the category of self loading stretchers; that of a scarce manoeuvrability

due to the use of only two pivoting wheels. When an increased manoeuvrability of the stretcher is required, the activating of a lever will enable the fixed front wheels of the trolley to rotate freely and by simply letting go of the lever, return the wheels to their natural state. Spencer, always looking to improve the working conditions for operators, have, with Twist introduced a system that optimises manoeuvrability, reduces the strain on the lumbar region which can be caused every time that it is necessary to change direction.

Twist was created to fill a gap in the category of self loading stretchers; that of a scarce manoeuvrability

due to the use of only two pivoting wheels. When an increased manoeuvrability of the stretcher is required, the activating of a lever will enable the fixed front wheels of the trolley to rotate freely and by simply letting go of the lever, return the wheels to their natural state. Spencer, always looking to improve the working conditions for operators, have, with Twist introduced a system that optimises manoeuvrability, reduces the strain on the lumbar region which can be caused every time that it is necessary to change direction.Self effect

The Self system allows for the transportation of the load without the usual risk of injury that an operator can face during the lifting phase. It completely sustains loading or unloading, into or off the vehicle. The inferior part of the stretcher has an articulation that, during closure can be activated, not by a lifting movement but, by a simple pushing action. With this, the wheels with which it is equipped are easily brought into contact with the surface onto which it has to be loaded. The advantage of this system is that the load can be made to slide without any extra effort. This system therefore, on one hand eliminates any risk of strain on the lumber region of the operator, and on the other, in its role as a trolley, presents itself as highly stable and easy to handle. All this is due to the well balanced structure and a notable smoothness when in motion. The wheels have a diameter of 200 mm which also contribute to the quality of this stretcher. This has all been achieved while maintaining a low weight and perfect balance. Thanks to the Self system, the risk of injury to the lumbar region of the operator is eliminated as only

a simple pushing movement is required.

Thanks to the Self system, the risk of injury to the lumbar region of the operator is eliminated as only

a simple pushing movement is required. The stretchers that are not equipped with the Self system require lifting during both the loading and unloading

phases with a subsequent risk to the rachis.

The stretchers that are not equipped with the Self system require lifting during both the loading and unloading

phases with a subsequent risk to the rachis.

Crash assist

Always looking for solutions of the most extreme of cases, Spencer has improved absorption still further with Crash-assist. Centre of gravity shifted, compensated piston, auxiliary framework. Result: a drop range of only

190 mm.

Always looking for solutions of the most extreme of cases, Spencer has improved absorption still further with Crash-assist. Centre of gravity shifted, compensated piston, auxiliary framework. Result: a drop range of only

190 mm.

Silence

The silence of the gears is accentuated and therefore appreciated during transportation. The insertion of a self-oiling system in nylon between the metallic parts ensures a continuous silence and durability. What is very impressive is the total absence of vibration, maintained balance and deadening of any noise even when used on roads.

The silence of the gears is accentuated and therefore appreciated during transportation. The insertion of a self-oiling system in nylon between the metallic parts ensures a continuous silence and durability. What is very impressive is the total absence of vibration, maintained balance and deadening of any noise even when used on roads.

Wheels

Wheels with a diameter of 200 mm offer increased smoothness without requiring extra effort. Wheels forged in an extremely light and elastic copolymer, that glide on precision ball-bearing pads of rubberised “soft” polyurethane. The adoption of spherical pads for both the pivoting of the supports and the rotating axis of the wheels, along with the use of an elasticised rubber covering, contributes considerably to the reduction of noise even on uneven surfaces. The elasticity of the polyurethane covering, guarantees maximum comfort since, thanks to the high shock absorption capacity, absorbs irregularities of the ground thus avoiding the transmission of any vibrations or jolting to the stretcher. he design of the outrunner assures silence and a perfect adherence to the ground. The special technique used in the making of the ring, gives concentricity without ovalization thus guaranteeing a uniform rotation.Brakes

An integrated braking system allows the trolley to remain stationary on slopes, easy steering and the blocking of the trolley in the desired position. The procedure of braking, made easier by the use of a wide pedal, is gentle, requires no extra effort or regulation and simultaneously blocks both wheel and support. The wheels with diameters of 100, 125, and 150 mm, have supports made in acetyl resin with the double spherical crown type rotating parts.

The wheels with diameters of 100, 125, and 150 mm, have supports made in acetyl resin with the double spherical crown type rotating parts.

The wheels with a diameter of 200 mm, are made in cold pressed, chromium plated steel or stainless steel and have the double spherical crown type rotating parts.

The wheels with a diameter of 200 mm, are made in cold pressed, chromium plated steel or stainless steel and have the double spherical crown type rotating parts.

Ergonomic design

We believe that good design must begin with a full understanding of the function of a product. This, for us, means taking into consideration the simple operations of opening, closing, clamping, regulating or transferring and then analysing each separate element with regards to the operators interaction with the stretcher. We study these elements therefore, not only to have an aesthetically pleasing appearance and a comfortable grip but also to render the operators work easier when using our stretchers. This can be seen by now taking a closer look at the instruments used for manoeuvring. The lever used for the selection of the height required, has a slightly curved shape that thickens towards the end to offer the possibility of a comfortable and safe grip for the hand of the operator.

The lever used for the selection of the height required, has a slightly curved shape that thickens towards the end to offer the possibility of a comfortable and safe grip for the hand of the operator. The knob used to select the required length of the telescopic sleeves, has a space created to allow for the correct positioning of the thumb to guarantee a gentle yet safe activation.

The knob used to select the required length of the telescopic sleeves, has a space created to allow for the correct positioning of the thumb to guarantee a gentle yet safe activation.